A Continuous Variable Transmission is also referred as CVT and is a result of crafty engineering efforts. It helps the drivers to attain better fuel efficiency as well as smooth ride and drive. This blog helps to understand CVT transmission and explains its working mechanism with the engine.

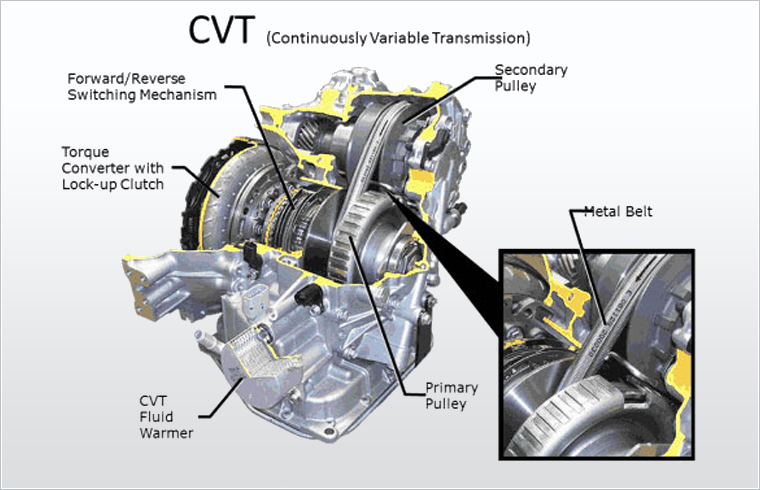

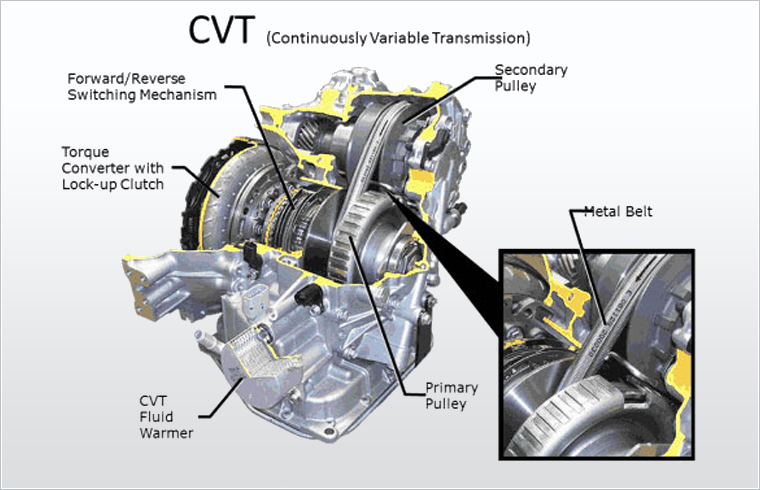

The CVT system consists of pulley system and it is connected by a chain belt, there are cones at each pulley which are connected by the chain belt. The cones work to decrease or increase the diameter by which the belt functions. There are few factors that determine pulley functioning and cones working such as the engine speed, vehicle speed and pedal position.

These factors are crucial to adjust the ratio and the combination of these factors help to change the ratio accordingly and the ratio is based on the best combination of fuel efficiency and speed. It is important to note that the CVT system doesn’t work as the conventional gearbox works. Some of the vehicles have buttons for CVT system and the buttons help to pre-adjust the ratio.

It is important to mention that the CVT system is much smoother than the traditional transmission; it is even smoother than automatic transmission. However, the CVT system has an un-even feel when you are accelerating hard. The CVT system has been designed with extensive engineering efforts as it consists of series of complex mechanisms and collection of gears, all work simultaneously and together.

There are large numbers of modern vehicles equipped with the CVT systems because it delivers better fuel efficiency as a whole. The Nissan 2013 Altima is equipped with the CVT system, and classified as one of the most fuel efficient car out there as it returns 38mpg. Apart from that, all the hybrid models such as Toyota hybrid come up with the CVT systems.